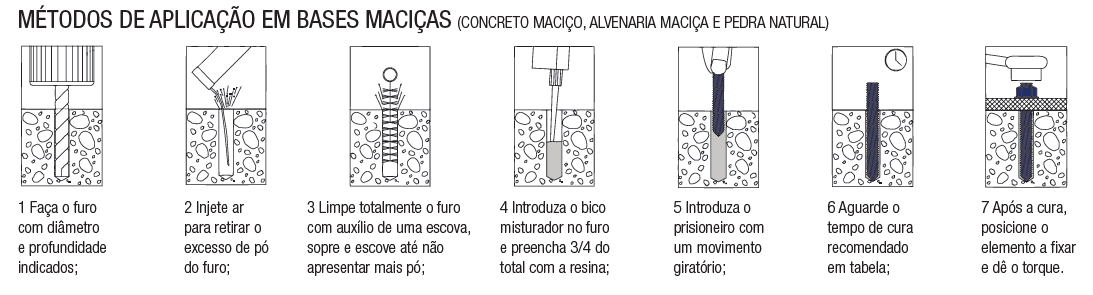

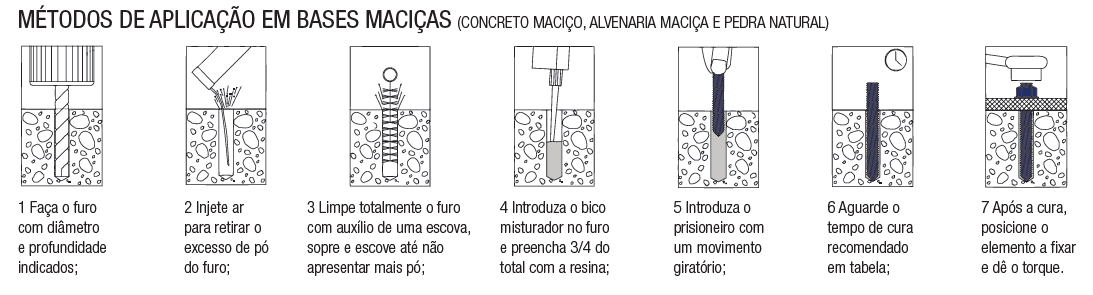

Image01: Methods of application on solid foundations (solid concrete, solid masonry and natural stone) 1 Drill the hole with the indicated diameter and depth;

Image02: 2 Inject air to remove excess powder from the hole;

Image03: 3 Thoroughly clean the hole with the aid of a brush, blow and brush until there is no more dust;

Image04: 4 Insert the mixing nozzle into the hole and fill ¾ of the total with resin;

Image05: 5 Insert the stud with a twisting motion;

Image06 6 Wait for the curing time recommended in the table;

Image07 7 After curing, position the element to be fixed and torque.

Technical data for installation in solid concrete Fixing rebar

| Rebar diameter – Do |

Hole (mm) |

Traction load (kgf)* |

Applications** |

| Diameter – Df |

Depth – hef |

400 ml |

| 8 mm |

12 |

80 |

2338 |

57 |

| 10 mm |

13 |

90 |

3133 |

51 |

| 12,5 mm |

16 |

120 |

4495 |

26 |

| 16 mm |

20 |

145 |

6595 |

14 |

| 20mm |

25 |

170 |

11958 |

7 |

| 25 mm |

32 |

225 |

17352 |

3 |

| 32 mm |

40 |

290 |

32940 |

2 |

*Last resin load in 28 Mpa concrete. Values obtained together with the parameters described in the respective tables. For practical applications a safety factor must be used (see page 49).

** Number of applications per tube under ideal installation conditions.

Concrete

Concrete Hollow Block

Hollow Block Rock

Rock Drywall

Drywall Cement Board

Cement Board Wall Panel

Wall Panel Wood

Wood OSB

OSB Structural Steel

Structural Steel Metal Tile

Metal Tile Aluminum

Aluminum Guides and amounts

Guides and amounts